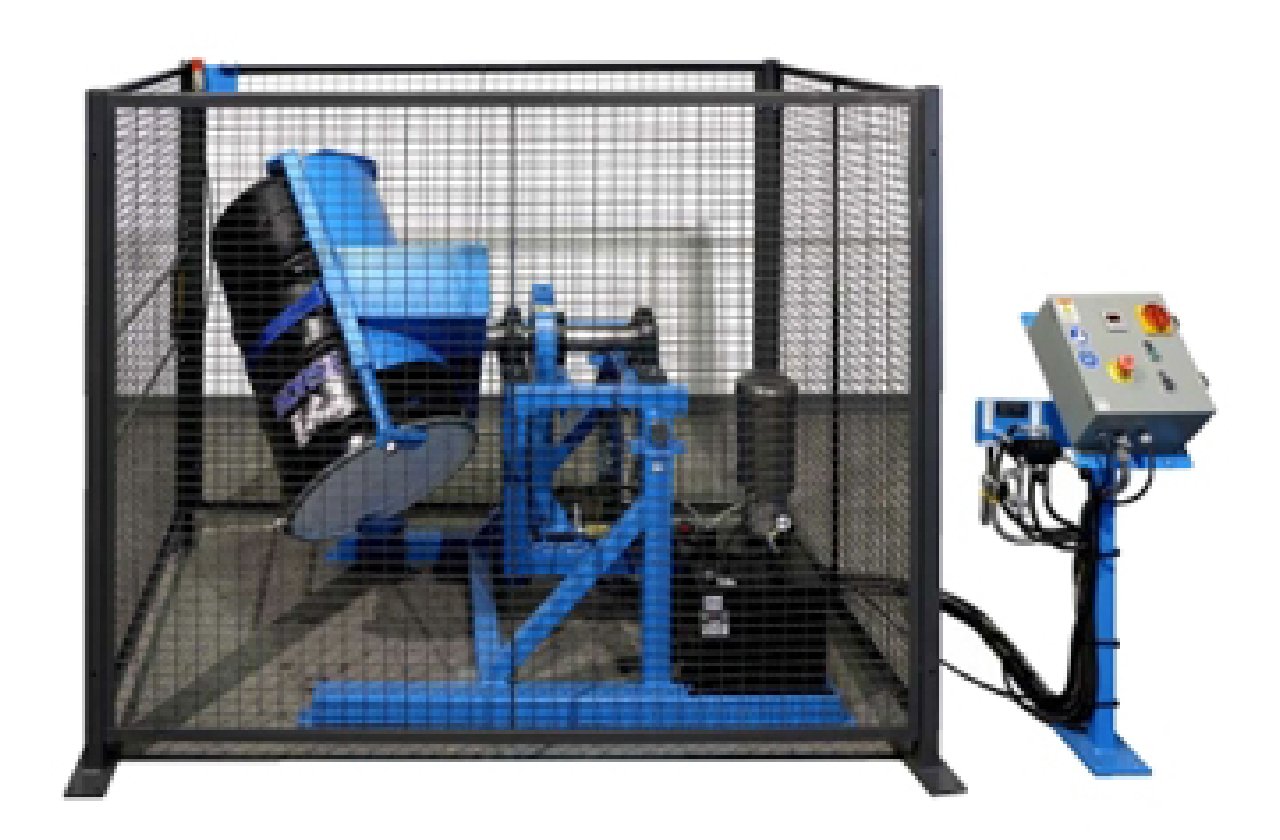

Tilt to Load Drum Tumblers

Introducing Tilt-to-Load Drum Tumblers, the perfect solution for efficient drum mixing. With a robust capacity of 800 lbs for full drums and 400 lbs for half-full drums, these tumblers can handle plastic, steel, or fibre drums. Experience a thorough corner-over-corner mixing action with rotation speeds ranging from 5 to 10 RPM (60Hz/air models) or 4 to 60 RPM (50Hz models).

Our Drum Tumblers accommodate drums measuring 29″ to 37″ in height and 18″ to 23.5″ in diameter. No need to purge containers between batches as each batch has its own drum. Say goodbye to spills, contamination risks, and hazardous splashing, ensuring worker safety. For enhanced control, we offer a separate Control Package tailored to your model and power supply. Start the drum rolling with power controls, while the control mast can be conveniently positioned outside the safety enclosure.

Ensure compliance with OSHA requirements by opting for our Morse enclosures with safety interlock (sold separately). These enclosures feature a gate safety interlock that automatically shuts off the drum roller when opened. To operate, simply open the gate, place your drum into the roller, and close the gate securely.

Benefits of Tilt-to-Load Drum Tumblers

- Efficient Mixing: Achieve thorough corner-over-corner mixing action for plastic, steel, or fibre drums.

- Versatile Capacity: Handles up to 800 lbs for full drums and 400 lbs for half-full drums.

- Batch-to-Batch Convenience: Each batch has its own dedicated drum, eliminating the need to purge containers.

- Improved Safety: Prevent spills, contamination risks, and splashing of hazardous contents on workers.

- Reliable and Durable: Designed by Morse, a trusted manufacturer known for quality drum handling equipment.

- Gripping Mechanism. Clamp

- Motor Models. 1-phase electric motor, 3-phase electric motor, an explosion proof 1-phase electric motor, an explosion proof 3-phase electric motor and an air motor.

- Movement Using a Tilt-to-Load Drum tumbler is as easy as 1,2,3. First load the upright drum at floor level, then secure the drum in the holder and finally power lift and rotate.

- Weight Capacity. 800 lbs

- Design For Moving drums weighing up to

800 lbs. - Controls. The control box includes: a timer, start & stop buttons, a red emergency stop button, 24V DC control supply, and lockable main disconnect to shut off &lock out power to the unit.

- Safety Features Built-in safety feature controls prevent accidental release of the drum

- Number of Users. 1 User

Bishamon EZX Loaders

This ergonomic solution immediately resolved our customer’s concerns and increased productivity.

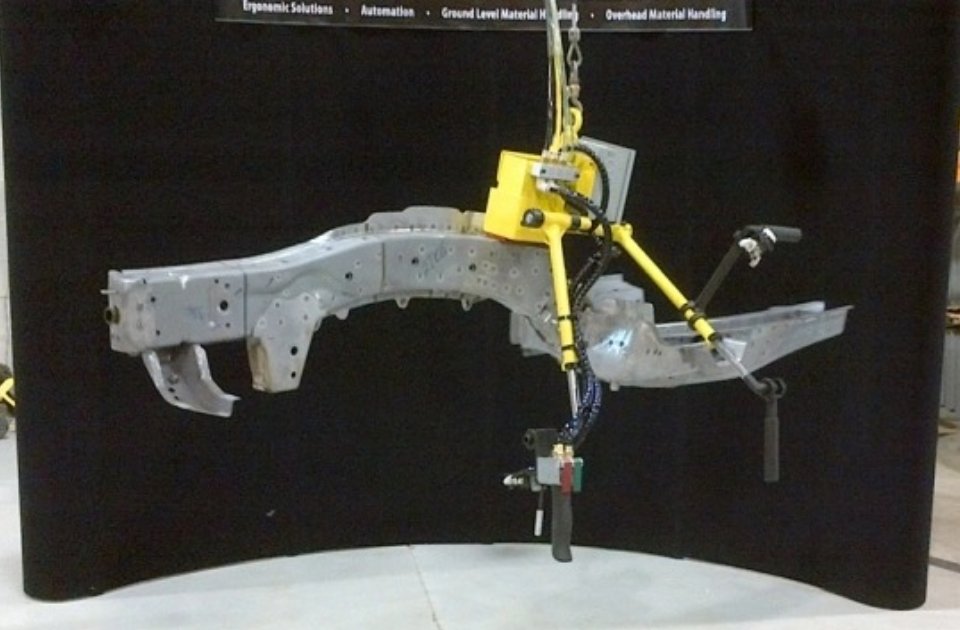

Custom Lift Assist

R&D Ergo designed and built this custom lift assist for a local major automotive manufacturer.

Ergonomic Lift Assist

Ergonomic custom design and build of a lift assist to lift and transfer a 23kg automotive part from a conveyor into a weld cell jig.

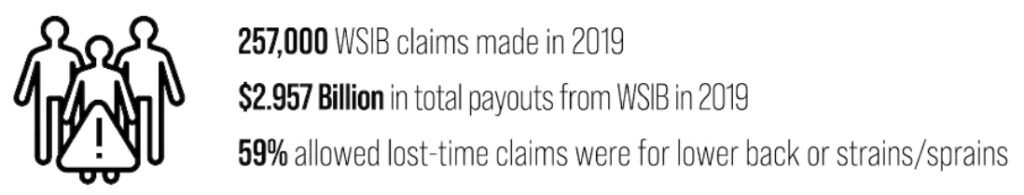

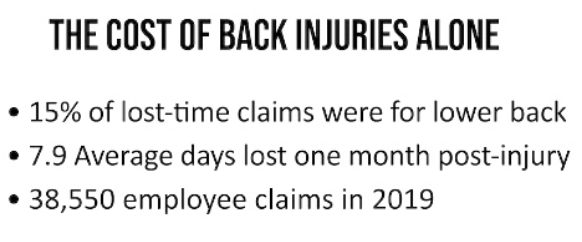

A Guide to Workplace Musculoskeletal Disorders

Your Perfect Solution Awaits!

Request a Quote

Related Products

Forklift Quick-Claw Drum Handling Unit

These cam locks help to secure the forks of the forklift in order to prevent any chance of the drum handling unit sliding off during a sudden stop.

Eagle-Poly Grip Drum Handling Attachment

Forklift attachment system for European plastic drums that have been steadily increasing in usage worldwide.

Eagle Grip 1 Forklift Drum Handling Equipment

These pieces of forklift handling equipment are designed in order to allow you to safely and efficiently be able to move drums throughout your facility.

Request a quote

Have questions?

Give us a call. Our friendly customer service staff are on hand to help you.