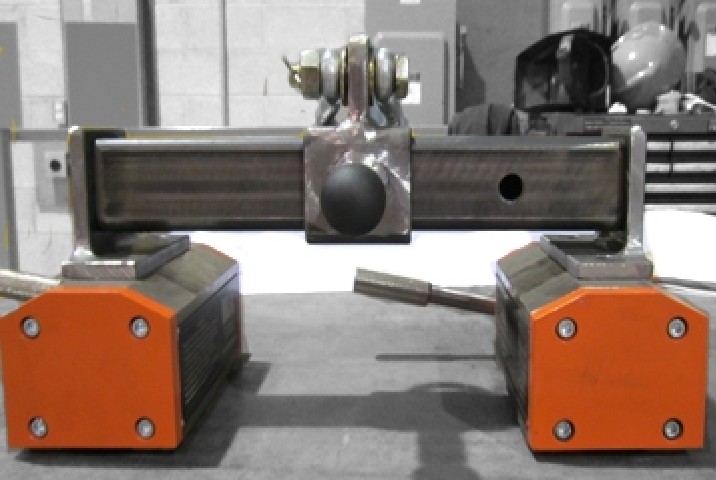

Magnetic End of Arm Tooling

Magnetic End of Arm Tooling devices are the go-to choice for industries handling large steel components, such as sheet metal, automotive parts, construction components, machine dies, and hydraulic cylinders.

Designed for efficiency, these systems excel in manufacturing and automotive sectors where metal parts are prevalent and their magnetic properties enable secure and reliable lifting operations.

benefits of Magnetic End of Arm Tooling devices

- Efficient: Streamline operations by securely lifting large steel components with ease.

- Versatile: Ideal for sheet metal, automotive, construction, and more.

- Reliable: Magnetic properties ensure a secure grip on magnetic items.

- Time-saving: Speed up handling processes for increased productivity.

Clamp End Effector

This factory decided that it needed a faster more effective way to move around delicate, but heavy parts.

Gripper End Effector to Move Transfer Cases

R&D Ergo designed this Gripper End of Arm Tooling device for a customer in the automotive manufacturing industry located in Mexico.

Gripper End of Arm Tooling

This Gripper End of Arm Tooling device was designed with the automotive industry in mind.

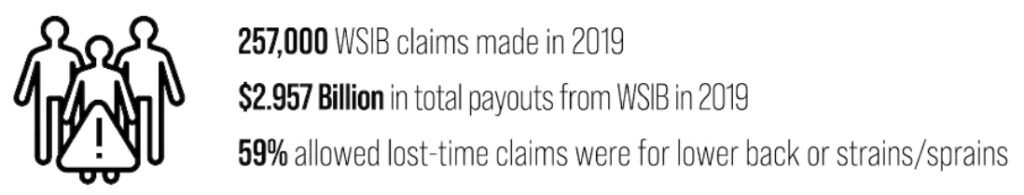

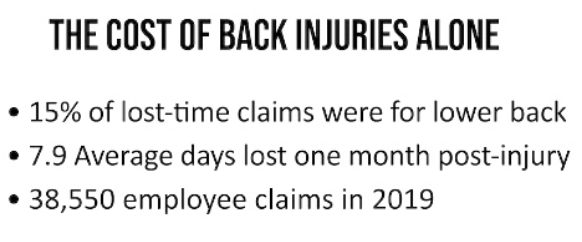

A Guide to Workplace Musculoskeletal Disorders

Request a Quote

Related Products

Clamp End Effectors

Specializing in picking up and moving items, these clamp end effectors have two metal pieces that tighten in order to lift up the desired item.

Gorbel End of Arm Tooling

Gorbel End of Arm Tooling offers high-speed, precise, and intelligent lifting capabilities, enhancing efficiency. It complements the system with custom end tooling for a comprehensive solution.

Magnetic End of Arm Tooling

Magnetic End of Arm Tooling is designed for efficient handling of large steel components, such as sheet metal, automotive parts, and machine dies, offering convenience and precision.

Request a quote

Have questions?

Give us a call. Our friendly customer service staff are on hand to help you.