End of Arm Tooling

What is End of Arm Tooling?

End Effectors also called End-Of-Arm-Tooling (EOAT), are devices that are able to complete a wide variety of tasks, and are attached to the end of an overhead lifting system. These devices are designed to act as the wrists/hand of the structure and allow the system to interact with the environment.

End of Arm Tooling & R&D ERGO

With over 25 years of End of Arm Tooling (EOAT) experience, we can design, engineer, build, install, and service custom systems designed with your specific application in mind. We combine innovation with experience in order to create an infinite variety of end-effectors based on what you need them to accomplish.

With our complete design, engineering, fabrication, and installation teams, we are able to rigorously test and refine our systems in order to create solutions for whatever task you wish to accomplish, whether that is improving productivity or an ergonomic solution. Over the past 25 years, we have developed strong partnerships with many major international suppliers, which has allowed us to select the best materials and products to create the most innovative solutions for the industries that we service (Manufacturing and Automotive, Food and Beverage, Pharmaceutical and Hospital, Warehouse and Retail).

Products

Clamp End Effectors

Specializing in picking up and moving items, these clamp end effectors have two metal pieces that tighten in order to lift up the desired item.

Gorbel End of Arm Tooling

Gorbel End of Arm Tooling offers high-speed, precise, and intelligent lifting capabilities, enhancing efficiency. It complements the system with custom end tooling for a comprehensive solution.

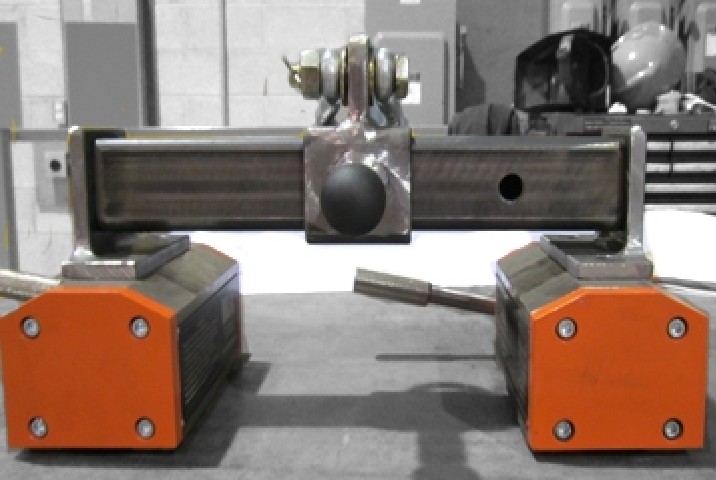

Magnetic End of Arm Tooling

Magnetic End of Arm Tooling is designed for efficient handling of large steel components, such as sheet metal, automotive parts, and machine dies, offering convenience and precision.

Gripper End Effectors

Gripper End Effector Systems offer versatile handling solutions with various styles, including two-finger grippers, widely utilized in industrial settings for efficient and reliable material handling.

Manual End Effectors

Manual End Effectors provide flexible handling solutions, offering both manual and mechanical operation. They are well-suited for simple and repetitive tasks, enhancing efficiency in various operations.

Pick and Place Lifting Devices

These Pick and Place End of Arm Tooling systems specialize in moving one item from one location to another.

Vacuum End Effector

Vacuum End Effectors are used in many different versatile ways and are capable of moving large items of significant weight.

What are the Benefits of a Material Handling System?

Increase productivity

Improved ergonomic processes

Boost employee satisfaction

Reduce the risk of musculoskeletal disorders

Reduce the risk of costly violations

Lower costs compared to fixed systems

Featured projects

Request a Quote

What our clients are saying

About R&D ERGO LTD

Resource Center

Learn from experts about safety within your industry. Browse our Resource Center to find case studies, articles, catalogues and more.

Customer Service

Our team is committed to providing the highest level of customer service. If you didn’t find the information you were looking for, contact us.

Request a quote

Have questions?

Give us a call. Our friendly customer service staff are on hand to help you.