Plastic and Fiber Drum Handling

Plastic and fibre drums are often extremely unstable during pickup and pouring operations due to the flexible side walls of the drums. Through the installation of a stabilizing collar, also called a drum support, around the top flange, plastic and fibre drums can now be rotated and picked up safely.

During the squeeze operation at drum pickup, the stabilizing collar makes use of the tabs that mate with the lifter grippers. To assist in maintaining position, the collar keeps the drum walls from deforming during the pour operation. Once the drum’s contents have been poured out, the collar is then removed and reassigned to the next drum that requires dumping. The primary focus of these designs is to produce an ergonomic solution while maintaining a Clean Room Finish (CRF). Solve your plastic and fibre drum material handling problems today and ensure that you are able to safely and efficiently move and use drums of all materials.

The benefits of using a stabilizing collar for plastic and fibre drums

The benefits of using a stabilizing collar for plastic and fibre drums are enhanced safety, improved stability during pickup and pouring, reduced risk of spills, and increased efficiency in material handling operations. The collar ensures secure rotation, prevents drum deformation, and offers ergonomic handling with a clean room finish. Solve your drum handling challenges and optimize efficiency today.

- Gripping Mechanism. Clamp

- Designed For. Lift-O-Flex &

Squeeze-O-Turn. - Movement To disengage the Clamp and Go from your dolly and then quickly connect to another, simply use your steel-toe boot.

- Weight Capacity. 500 lbs, depending on model

- Design For Moving drums made of plastic.

- Controls. Manual clamp

- Safety Features Built-in safety feature controls prevent accidental release of the drum

- Number of Users. 1 User

Custom Ergonomic Lift Assist Devices

We designed custom ergonomic lift assist devices for a major international automotive manufacturer.

Clamp Cart Door End Effector

This manufacturing plant required an end effector which would help them move parts such as the portable cart door

Custom Lift Assist

R&D Ergo designed and built this custom lift assist for a local major automotive manufacturer.

Contact us today in order to start reducing the danger that may be occurring in your workplace!

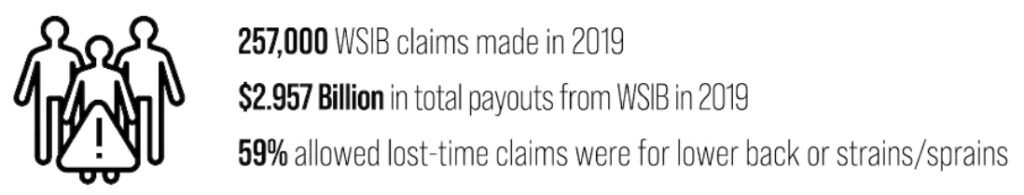

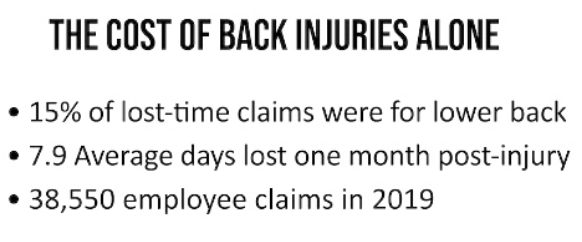

A Guide to Workplace Musculoskeletal Disorders

Your Perfect Solution Awaits!

Request a Quote

Related Products

Forklift Quick-Claw Drum Handling Unit

These cam locks help to secure the forks of the forklift in order to prevent any chance of the drum handling unit sliding off during a sudden stop.

Eagle-Poly Grip Drum Handling Attachment

Forklift attachment system for European plastic drums that have been steadily increasing in usage worldwide.

Eagle Grip 1 Forklift Drum Handling Equipment

These pieces of forklift handling equipment are designed in order to allow you to safely and efficiently be able to move drums throughout your facility.

Request a quote

Have questions?

Give us a call. Our friendly customer service staff are on hand to help you.