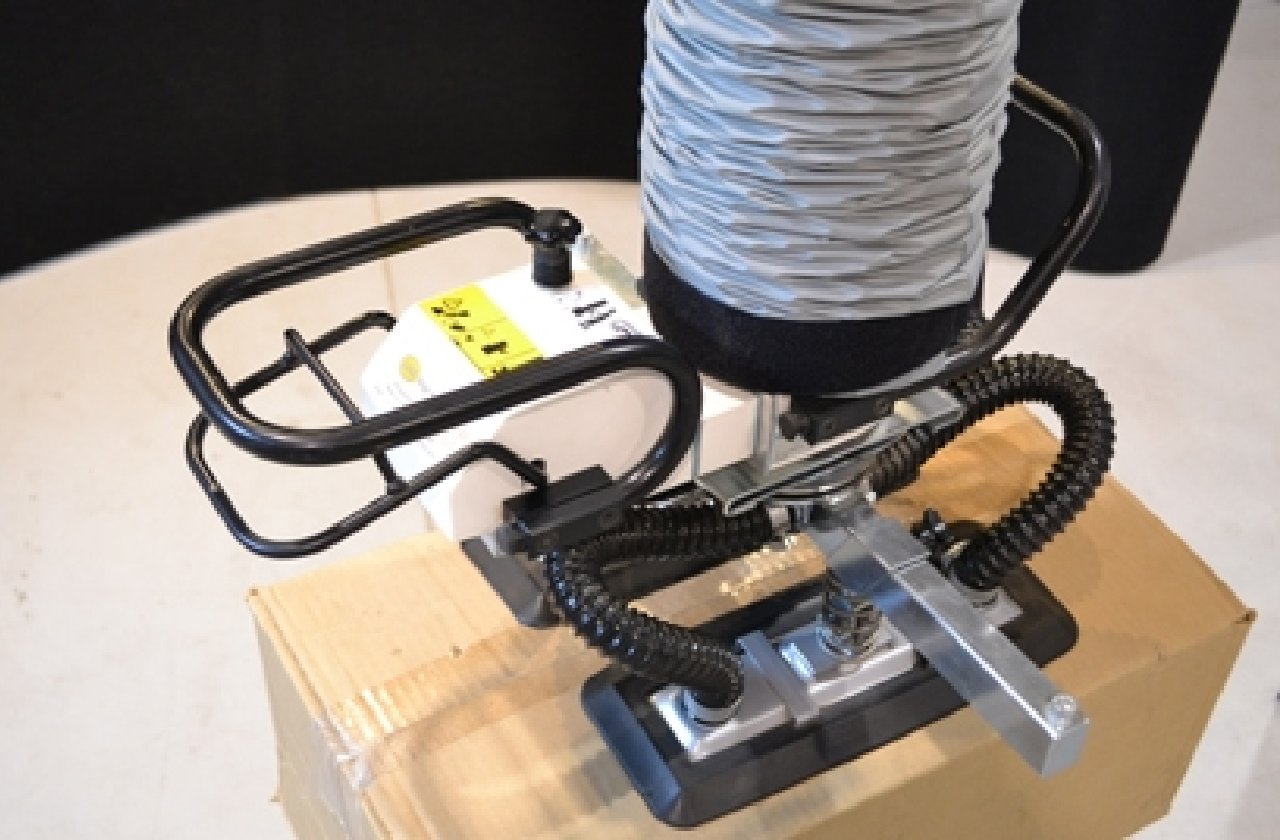

Lift-N-Go II™ Portable Lifter

Lift-N-Go II attachments

EXPAND-O-TURN

Electric core expander for paper and film rolls.

Load Platform

Allow operators to handle totes, boxes, roles and pails. Available in standard and custom sizes.

Core Probe

Available in a fixed or wheeled model, used to handle rolls from pick up to drop off.

V-Block

Lift-N-Go II Features and Benefits

| Features and Benefits | |

|---|---|

| Platform Maximum Weight | 200 lbs |

| Anodized Aluminum Profiles |

|

| Steel (Powder Coated Paint-Optional SS) |

|

| Standard Swivel Casters | Standard Length Lift Masts |

| Foot Operated Kick Brakes |

|

| Totally Enclosed Lift Mast with Ball Screw | Provides Safe Load Handling on the Down Movement |

| Current Limiting (No Limit Switches) | Smooth Up and Down DC Powered Movement |

| Electronic Power Pack | Quick Exchange Features for Multi-Shift Operation |

| Detachable Remote Controller | Operator Control Over Load Handling Functions |

| Adjustable Handlebar | Achieves Ergonomic Operation |

| Highly Maneuverable and Lightweight |

|

| UHMW Load Platform Dimensions |

|

Lift-N-Go II Specifications

| Lift Stroke | Total Height | Total Lift Height - Floor to top of Platform | ||

|---|---|---|---|---|

| 1550mm (56.7") | 1928mm (76") | 1692mm (60.9") | ||

| 1800mm (66.6") | 2178mm (85.8") | 1942mm (70.8") | ||

| SPECIFICATIONS | ||||

|

Minimum Lift Height Standard:

Lift Speed 200 HD Series: Length (w/o Platform): Load Platform (Depth x Width): Wheel Diameter (Front/Back): Maximum Load Series: Lifter Weight w/o End-Effector: Battery Voltage: Battery Capacity: Lifter Finish: |

158mm (6.2"), 108mm (4.25")

90mm/sec (3.5"/sec) 771mm (30.35") 440mm (17.3") x 560mm (22") 60mm (2.3") / 100mm (3.9") 90Kg (200-lbs) 40Kg (90-lbs) 24V 7.2AHr Powder Coater Paint/Anodized or Stainless Steel/Anodized |

|||

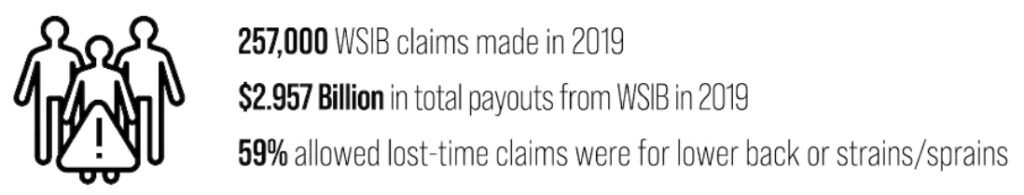

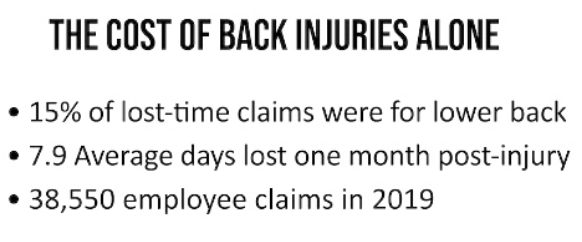

Regulations

All of our Material Handling solutions either meet or exceed all applicable regulations which include; OSHA, ANSI and ASME B30.20.

Resources

Resource Guide

Explore the Resource Guide, where cutting-edge design meets ergonomic excellence. Upgrade your safety and productivity.

Ergonomic Solutions Article

Our latest article shows how implementing different material handling solutions can prioritize your workers safety, productivity, and reduce costs!

OD Clamp Forklift Case Study

This is a simple solution for wineries, distilleries, or anyone else that works with wooden barrels or casks in terms of overall material handling safety.

A Guide to Workplace Musculoskeletal Disorders

Your Perfect Solution Awaits!

Request a Quote

Related Products

Box Handling Solutions

We at R&D Ergo Ltd have an extensive line of Ergonomic Box and Tote Handling Equipment designed to improve efficiency and eliminate workplace injuries.

Vacuum Box Handling Solution

A fixed Vacuum Lifting Solution is an ideal system for moving Boxes and Totes in a defined vicinity. Having provided countless fixed Vacuum Lifters to

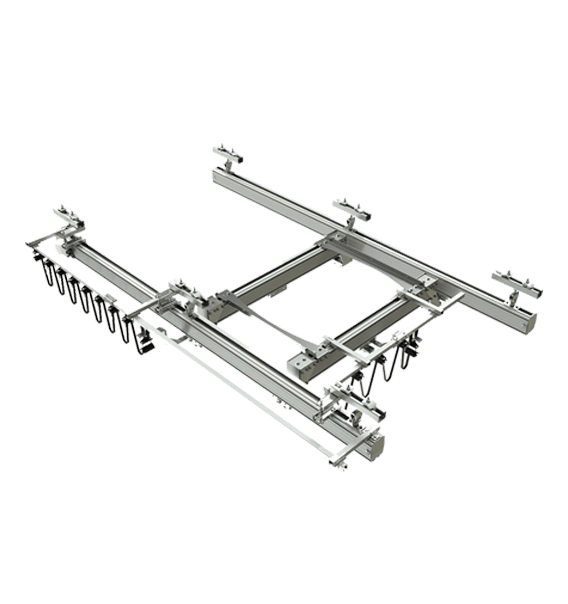

MechRail Rail System

The Mechrail rail system uses a variety of propulsion options, including manual and motorized, to accommodate different industrial needs.

About R&D ERGO LTD

Resource Center

Learn from experts about safety within your industry. Browse our Resource Center to find case studies, articles, catalogues and more.

Customer Service

Our team is committed to providing the highest level of customer service. If you didn’t find the information you were looking for, contact us.

Request a quote

Have questions?

Give us a call. Our friendly customer service staff are on hand to help you.