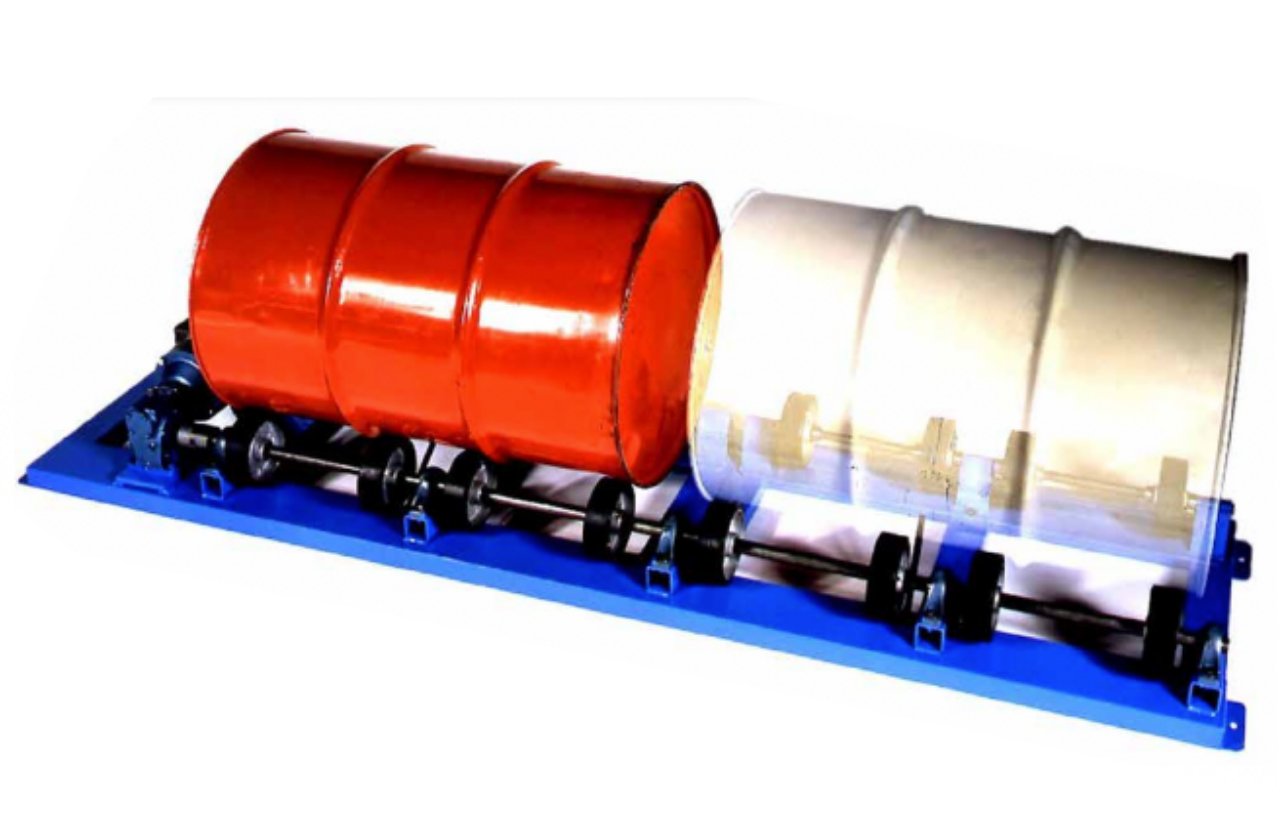

Double Stationary Drum Rollers

Upgrade your drum mixing process with Morse Double Stationary Drum Rollers. By blending ingredients directly inside sealed drums, you eliminate the need for transfer, specialized vessels, and additional apparatus, saving you valuable time, labor, and money.

Choose from our Variable Speed Control Packages and Fixed Speed Drum Rollers. Variable Speed Control Packages support liquid loads up to 1,000 pounds and offer RPM levels based on dry load capacities of 400, 300, and 250 pounds. Fixed Speed Drum Rollers accommodate liquid loads up to 1,000 pounds and dry loads up to 300 pounds. Our selection includes 7 models of Double Stationary Drum Rollers, each tailored to specific drum rolling requirements. Categories range from stationary drum rollers to non-explosion-proof and explosion-proof control packages, as well as guard enclosure kits. Find the perfect solution for your drum rolling needs with Morse.

benefits of Double Stationary Drum Rollers

- Efficient blending inside sealed drums, eliminating transfer and specialized vessels.

- Cost and labor savings by reducing clean-up and apparatus expenses.

- Versatile options with Variable Speed Control Packages and Fixed Speed Drum Rollers.

- Diverse models including guard enclosures and explosion-proof options.

- Improved safety by securely holding drums during mixing.

- Accessories. An idler attachment and a POLY-2-5154 that allows you to roll a 55-gallon drum on a stationary drum roller.

- Motor Models. 1-phase electric motor, 3-phase electric motor, an explosion proof 1-phase electric motor, an explosion proof 3-phase electric motor and an air motor.

- Movement AC Control Package and an Explosion Proof AC Control Package.

- Weight Capacity. Up to 1,000 lbs

- Design For Moving drums weighing up to

1,000 lbs. - Controls. Manual clamp

- Safety Features Built-in safety feature controls prevent accidental release of the drum

- Number of Users. 1 User

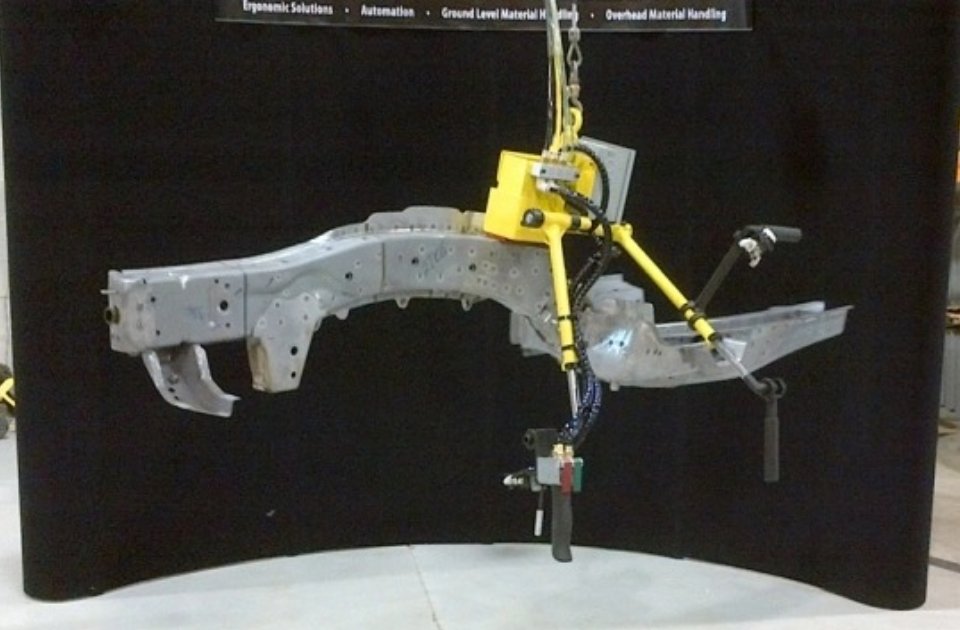

Ergonomic Lift Assist

Ergonomic custom design and build of a lift assist to lift and transfer a 23kg automotive part from a conveyor into a weld cell jig.

Lifting Solution for Plastic Dunnage Containers

One of our large international food company customers asked R&D Ergo to provide an ergonomic safe lifting solution for these plastic dunnage containers.

Custom Lift Assist

R&D Ergo designed and built this custom lift assist for a local major automotive manufacturer.

Contact us today in order to start reducing the danger that may be occurring in your workplace!

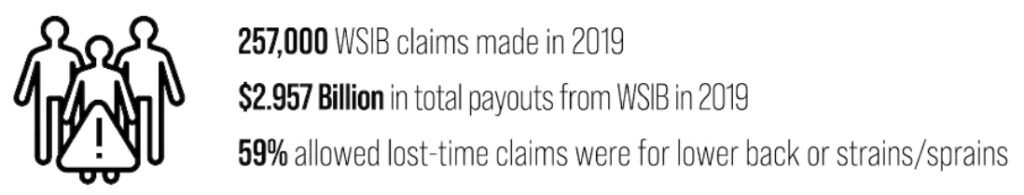

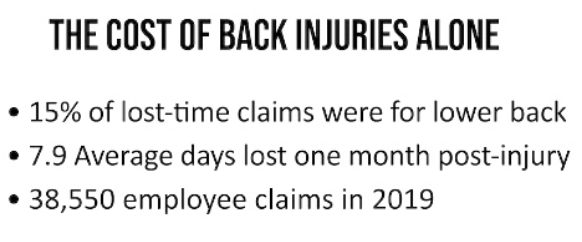

A Guide to Workplace Musculoskeletal Disorders

Your Perfect Solution Awaits!

Request a Quote

Related Products

Forklift Quick-Claw Drum Handling Unit

These cam locks help to secure the forks of the forklift in order to prevent any chance of the drum handling unit sliding off during a sudden stop.

Eagle-Poly Grip Drum Handling Attachment

Forklift attachment system for European plastic drums that have been steadily increasing in usage worldwide.

Eagle Grip 1 Forklift Drum Handling Equipment

These pieces of forklift handling equipment are designed in order to allow you to safely and efficiently be able to move drums throughout your facility.

Request a quote

Have questions?

Give us a call. Our friendly customer service staff are on hand to help you.