Related Articles

Material Handling and Ergonomic Solutions – Protecting the Backbone of Industries

Efficient material handling solutions are the unsung heroes of the manufacturing and warehouse industries. Dive in to discover how they boost productivity, reduce costs, and

10 Reasons You Could Benefit from A Cart Mover

Material Handling Solutions: Powered Cart MoversLifting Equipment

6 OHSA Changes Those Will Impact Ontario Employers

Amendments called the Stronger, Fairer Ontario Act, 2017 (Bill 177), have been made to the Ontario Occupational Health and Safety Act (OHSA) and went into

Vacuum Lifting 101

What is a Vacuum Lifter? Vacuum lifters are ergonomic devices used to transport a variety of products within a set area, such as a warehouse

7 Key Advantages to Using a Hydraulic Lift Table.

What is a hydraulic lift table? A hydraulic lift table is an ergonomic device utilized to raise, lower or tilt workloads such as pallets.

Seven Steps to Safer Behaviour

Creating – and maintaining a safe work environment should be a top priority for organizations. Under the Occupational Health and Safety Administration’s (OSHA) Law,

How to Prepare for an Incident?

Though you may take all of the proper preventative measures to decrease the chances of an injury occurring, they still happen and it is important

Safety Tip: Be Prepared for the WHIMIS Inspectors

Federal OHS inspectors will be visiting workplaces across the country to check for compliance with the new GHS/WHMIS2015 requirements starting October 1, 2017. What are

The Lifting Equation

Did you know that The National Institute for Occupational Safety and Health (NIOSH) has a lifting equation for calculating a recommended weight limit for

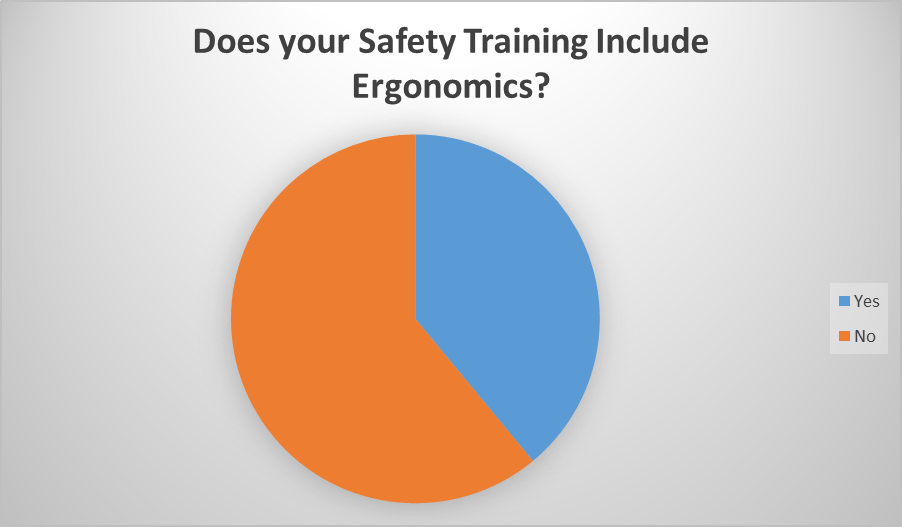

Ergonomics in the Canadian Workplace

Related to: How to Justify Ergonomic Improvements, Benefits of Ergonomic Solutions, Work-Related Musculoskeletal Disorders and Ergonomic Solutions The retention of human resources is a key factor

How to Cost-Justify Ergonomic Improvements 101

Related to: Ergonomic Solutions, Benefits of Ergonomic Solutions, Work-Related Musculoskeletal Disorders The ability to demonstrate the payback on ergonomic improvements is an ongoing challenge for many

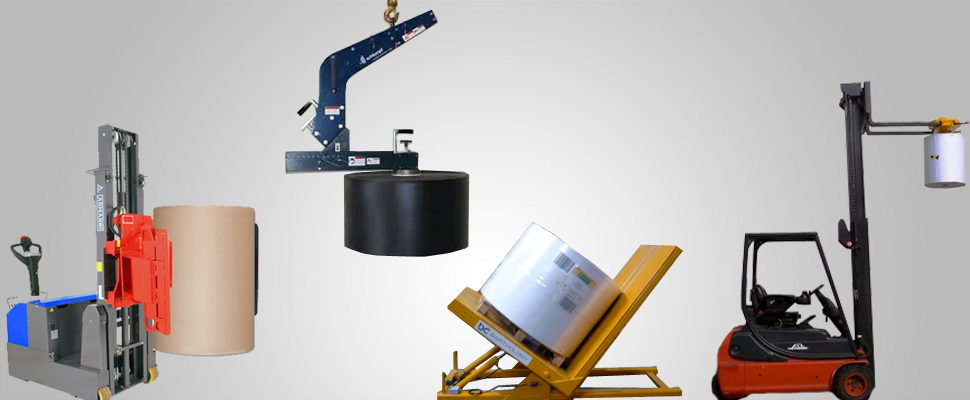

Roll Handling: What it is, Why it will Benefit You and What You Should Consider Before Purchasing

Related: Roll Handling Solutions, Hoist Based Roll Handling and Potable Roll Handling Roll handling is commonly defined as a method in which rolls of material